×

×

Many lessons have been learned over decades of providing service to and interacting with facility managers. Perhaps the easiest step which will minimize frustration by all parties is to clearly define the service call work-flow. IT IS IMPORTANT that a facility’s service vendors make clear and COMMUNICATE their preferred service response work-flow; this will enable a facility manager to either incorporate or request revisions to the work-flow.

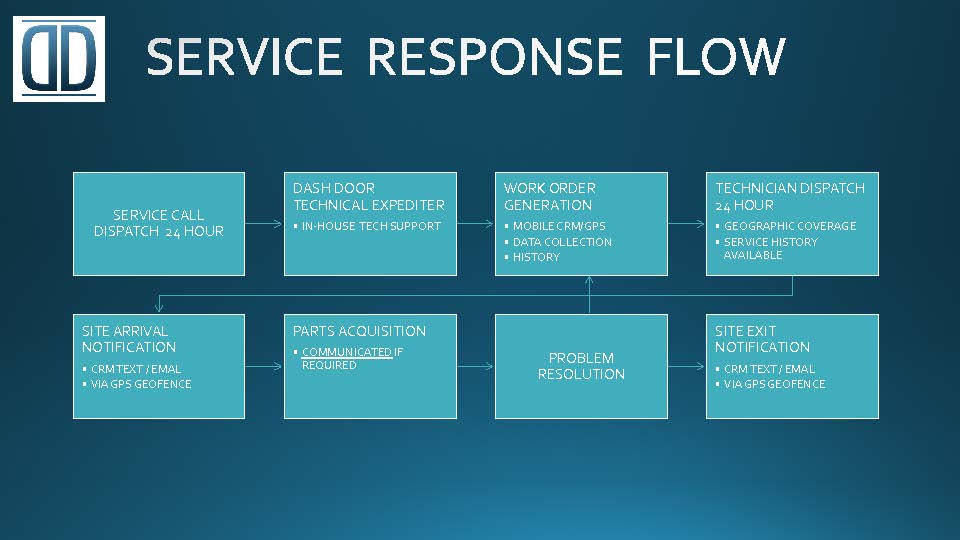

Presented here is a sample service call work-flow which a number of Dash Door facility manager clients have elected to utilize. There are many variations of this workflow; however, the basic elements of communication remain. This sample will not work for every facility; the important point is to have the discussion early with whatever type of vendor you are considering bringing aboard your team. Defining expectations formally will serve as a guide to evaluate performance and save time.

The backbone of a solid service / maintenance work-flow is a 24 hour dispatch capability. If this is not required by a particular facility, it is important to have responsive dispatch during the required working hours. Redundancy is key to any dispatch. Multiple dispatch staff must be sharing the SAME data. Service dispatch software integrated with the office network will ensure all are working form the same data.

While not necessary for some trades, the inclusion of a technical expediter for after-hours calls will ensure that a service technician has access to in-house technical support. This will often times mean the difference between a completed after-hours call and a call that must be revisited after a temporary fix has been employed. Two heads are better than one and the experience of a seasoned technical expediter does not cost the end-user added labor on the service call.

Work order generation may begin with a formal work order being issued by the facility being served. In any case, the service vendor will create an internal work order via the in-house dispatch / Customer Relationship Management (CRM) software. Location history and existing equipment warranty information may all be accessible via mobile applications available to today’s service technician via smart phone or tablet. The home office and service technician are working from a single work order via cloud / mobile network communication. Less data entry yields less human error, saved time / greater efficiency.

Technician dispatch is as easy as sending the work order to the desired tech via the dispatch board at the home office or any number of mobile management tablets that are also in the field. Integration of vehicle GPS adds another level of competency in being able to “survey the battlefield” and make intelligent “tactical” decisions regarding technician competencies and equipment they possess on their particular vehicles. Intelligent vehicle routing for on-the-fly work order assignments also saves time by considering existing traffic conditions. Technicians are able to be dispatched quickly without multiple phone calls and requests for directions.

Many software packages with GPS integration permit an imaginary boundary around the facility within the software called a “geofence”. When a work order is assigned to a particular tech, and that vehicle crosses into the geofence, a text and/or email may be automatically sent by the software to the facility manager(s) to notify of the service provider’s arrival. The clock starts ticking – this ability helps with time and material contracts in terms of tracking technician movements. Vehicle movements can be tracked on a large college campus for example with work status updates “In Process”, “Need Parts”, “Work Complete” being set by the technician via mobile device. It’s a brave new world!

If it is found that non-stock parts are required (or parts are not present on the responding technician’s vehicle), a “Parts Needed” status will be communicated to the facility manager representative. Communication of this status is important as is noting the lead-time of the required part. Any circumstances where parts are delayed by a manufacturer for example would be communicated to the end-user – it is always good to make those unsolicited “we haven’t forgotten about you” phone calls. Even with the technology available today, a service provider should understand that a phone call beats an email any day when it comes to communicating unforeseen delays or scheduling issues. Technology should be a tool – not a crutch.

The resolution of the problem at the initial service call or after a part has been ordered and installed, data collection for the service call is included in the history of the work order, location and equipment installed. Many service provider software packages permit access to this data through a web-based customer portal which shows outstanding invoices and location based history.

Similar to the geofence capability in the site arrival step, the same geofence may be employed to signal the exit of the responding technician to the end-user. Service call status may be elected to be communicated at this step rather than an intermediate communication step while on site. Many facility manager’s would rather receive a single notification upon exit along with the status of the call.

Again – the sample work-flow above is just that, a sample of steps which works for a number of our existing clients. There are many small variations preferred by other end-users. The main point again is to communicate the expectations and arrive at a work-flow that is acceptable and useable for both the service provider and the facility.