Factors Determining Proper Hinge Selection

There are a number of factors to consider when selecting a door hinge type and configuration. Stanley Hinges has provided an aid to review all considerations before making a final selection. As always, Dash Door’s Contract Door & Hardware Group reviews all of these considerations when estimating and detailing your project. The reference below is intended for end-users so that they may be more familiar with all factors used to determine proper hinge selection.

- Application

- Primary consideration is given to the type of door and frame for selection of a proper hinge configuration.

- Hinge Size

- Determined by door size, thickness, weight, frequency of use, and clearance required.

- Hinge Type

- The weight of the door and frequency of use determine whether a heavy weight, standard weight

anti-friction* bearing or, a plain bearing hinge should be used.

- Heavy weight hinges should always be used on heavy doors and doors where high frequency is expected.

Use anti-friction* bearing hinges on doors equipped with closers.

- Metal and Finish

- Determined by considerations such as atmospheric conditions, location of doors, or special conditions as in

chemical laboratories, sewage disposal plants, etc.

- While ferrous metal can be given a good rust-resisting base, it cannot be given the same absolute

guarantee against rust as nonferrous metals and should not be used for extreme exposure.

- Finish on hinges can be furnished to Stanley or ANSI/BHMA Standards.

- When an exact match of another manufacturer’s finish is desired, please submit sample.

- Fasteners

- Standard fasteners furnished with each hinge are specified in this catalog. Other fasteners are available and

must be clearly specified.

- Hand of Hinge

- Loose joint hinges, pivot reinforced, electric, etc. are handed and should be specified right or left hand.

- Hinge Edge of Door

- Is the door edge on the hinge side square or beveled?

- Tip Options

- Institutions often require hospital type tips (barrel ends sloped) making it difficult to attach rope, wearing

apparel, etc.

- Flat button tip is universally used as standard.

- Decorative tips and conversion kits are available for decorative effects.

- Special Hinge Types

- Raised barrel, electric hinges, pivot reinforced hinges, hinges with non-removable pins, security studs, etc.

- Quality Level, Budget

Number of Hinges Required

Use two hinges on doors up to 5′ (1.52m) and an additional hinge for each additional 2.5′ (.76m) or

fraction thereof.

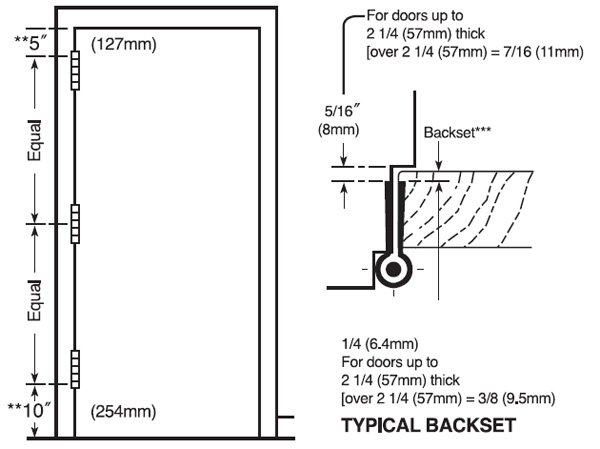

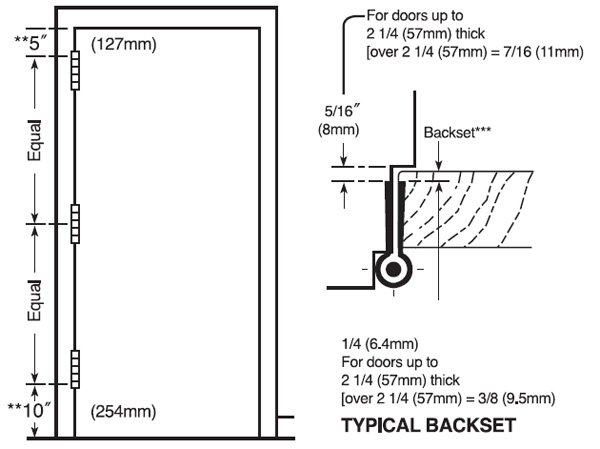

Location of Hinges on Doors

(US Standards Procedure)

Top hinge 5″ (127mm) from frame rabbet to top of barrel.

Bottom hinge 10″ (254mm) from bottom edge of barrel to finished floor.

Third hinge centered between top and bottom hinges.

* Anti-friction bearings include Lifestan® CB bearings and ball bearings

** Certain western states use as standard 7″ (178mm) from top and 11″ (279mm) from the bottom.

*** The suggested location for olive knuckle and paumelle hinges is 1/4″ (6.4mm) from pull side of door to edge of hinge leaf.

×

×